Pdca Plan Do Check Act Een Cyclus Voor Procesoptimalisatie Vrogue

PDCA or plan-do-check-act (sometimes called plan-do-check-adjust) is an iterative design and management method used in business for the control and continual improvement of processes and products. It is also known as the Shewhart cycle, or the control circle/cycle.Another version of this PDCA cycle is OPDCA. The added "O" stands for observation or as some versions say: "Observe the.

PDCA cyclus Plan Do Check Act uitleg 2 Deming cirkels

The Plan, Do, Check, Act (PDCA) framework is a robust methodology for continuous improvement that has gained widespread popularity in both business and non-business contexts. In essence, it is a structured problem-solving approach involving the eponymous phases: Plan, Do, Check and Act. The framework is used by organisations of all sizes and.

PDCA cyclus Plan Do Check Act uitleg 2 Deming cirkels

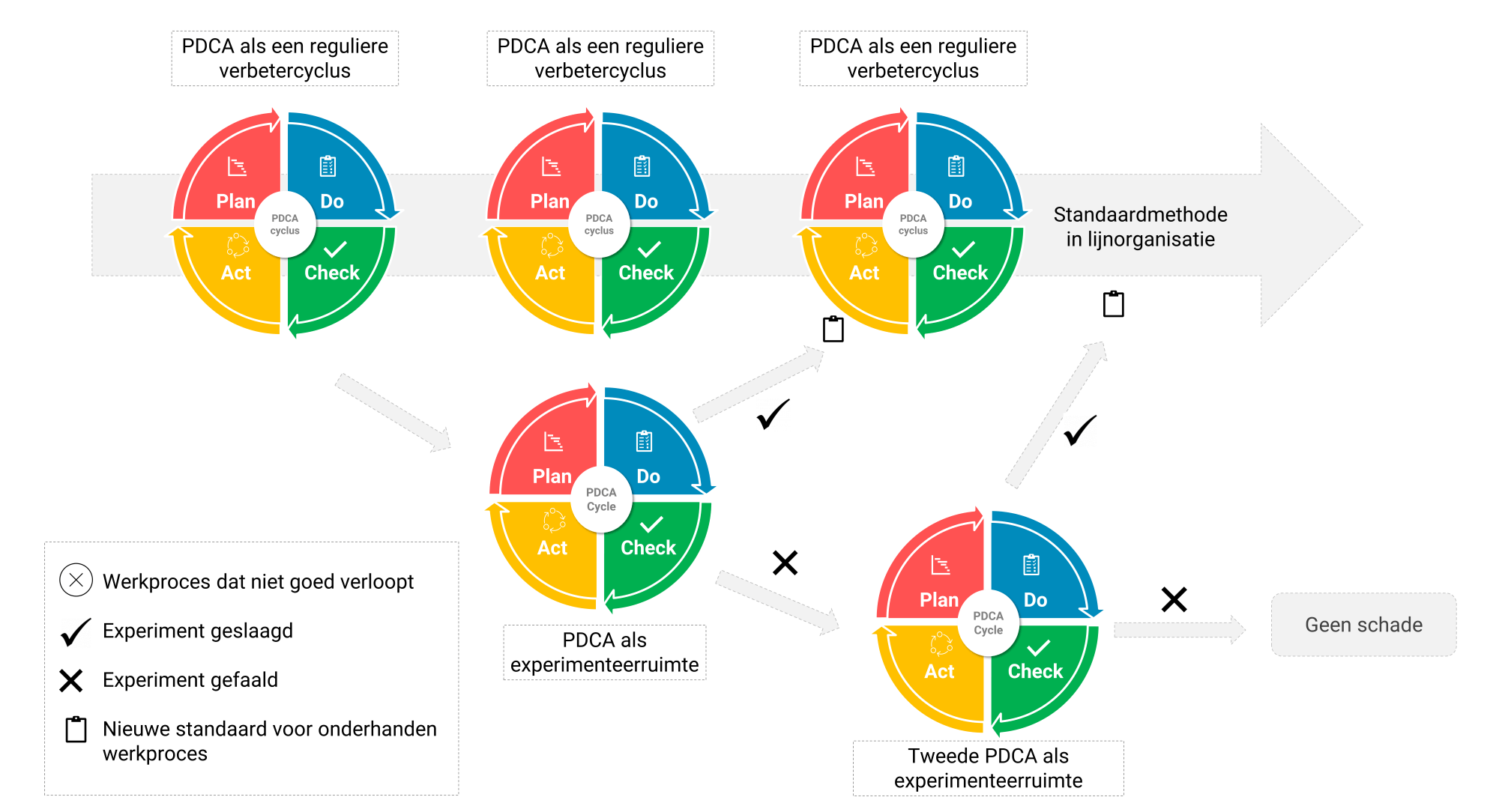

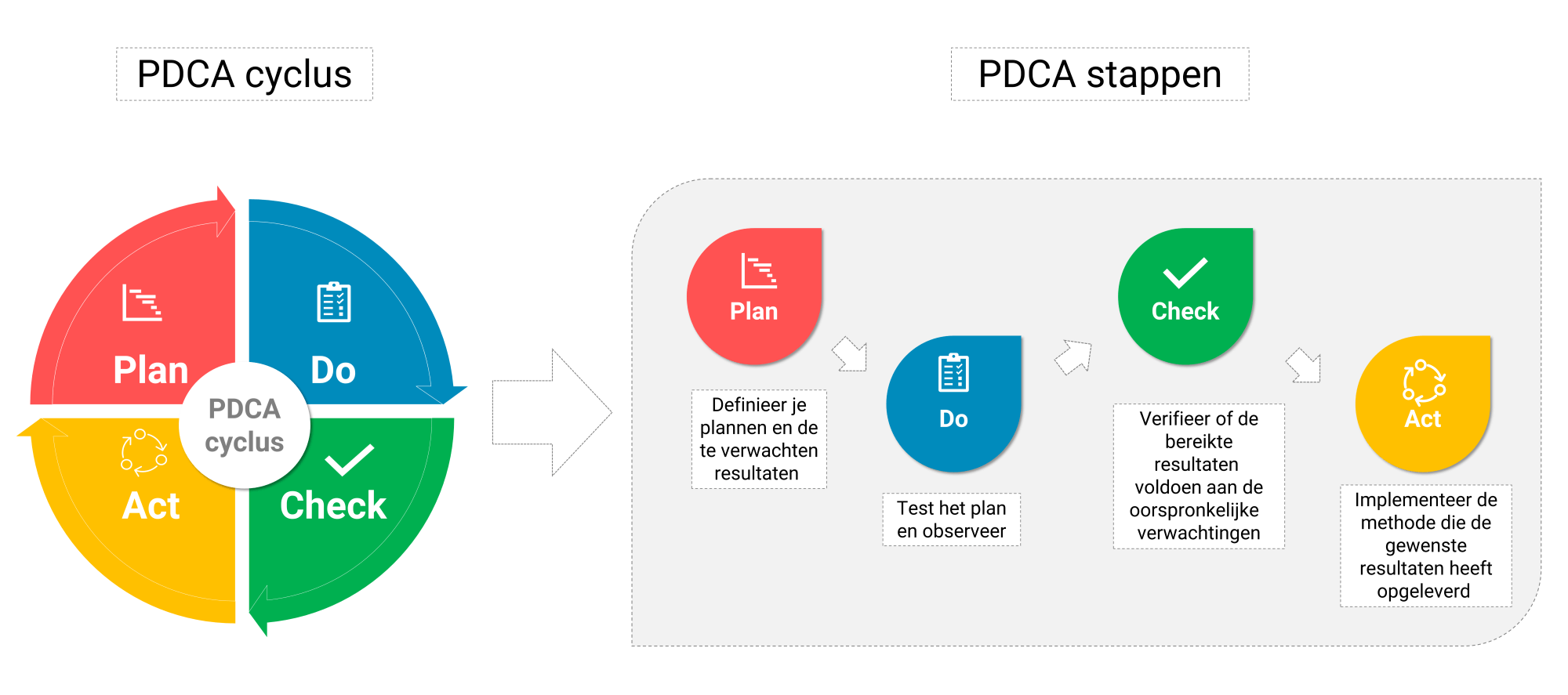

Key Points. The PDCA/PDSA cycle is a continuous loop of planning, doing, checking (or studying), and acting. It provides a simple and effective approach for solving problems and managing change. The model is useful for testing improvement measures on a small scale before updating procedures and working practices.

Description of Check Act Plan Do Model Business901

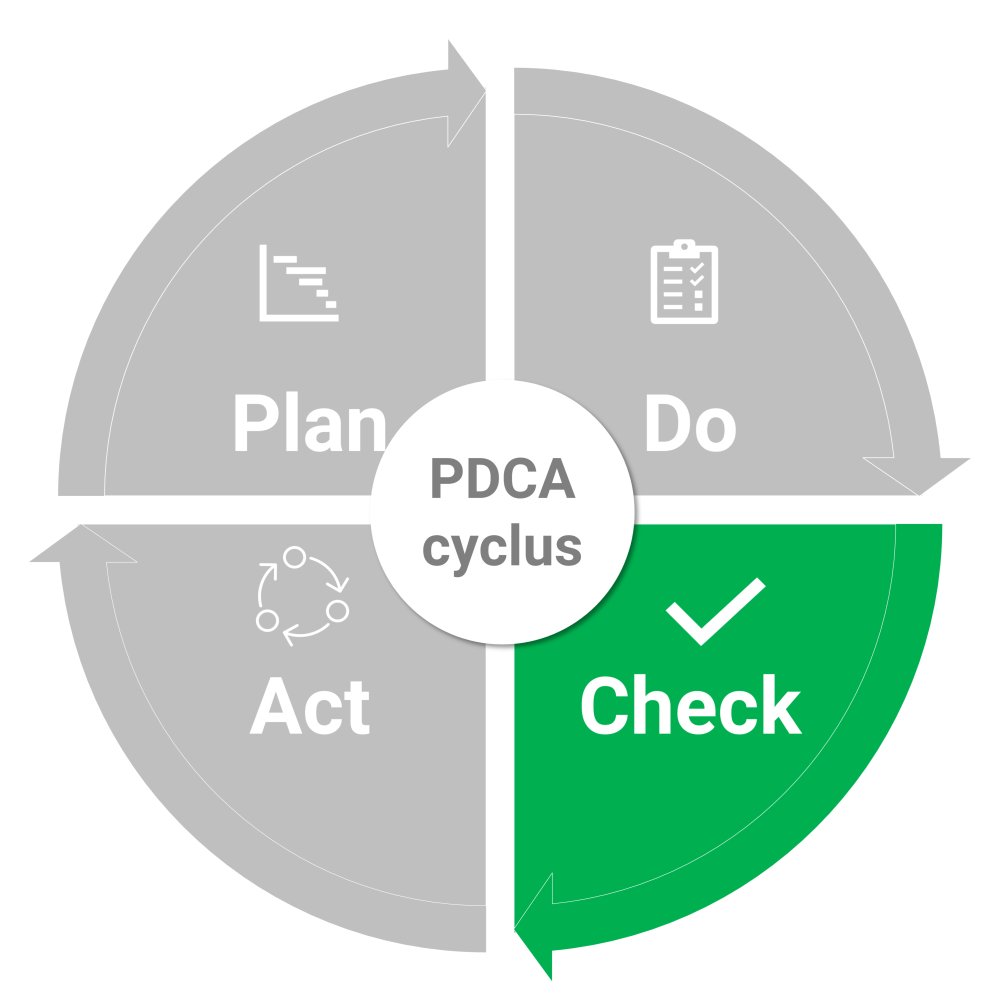

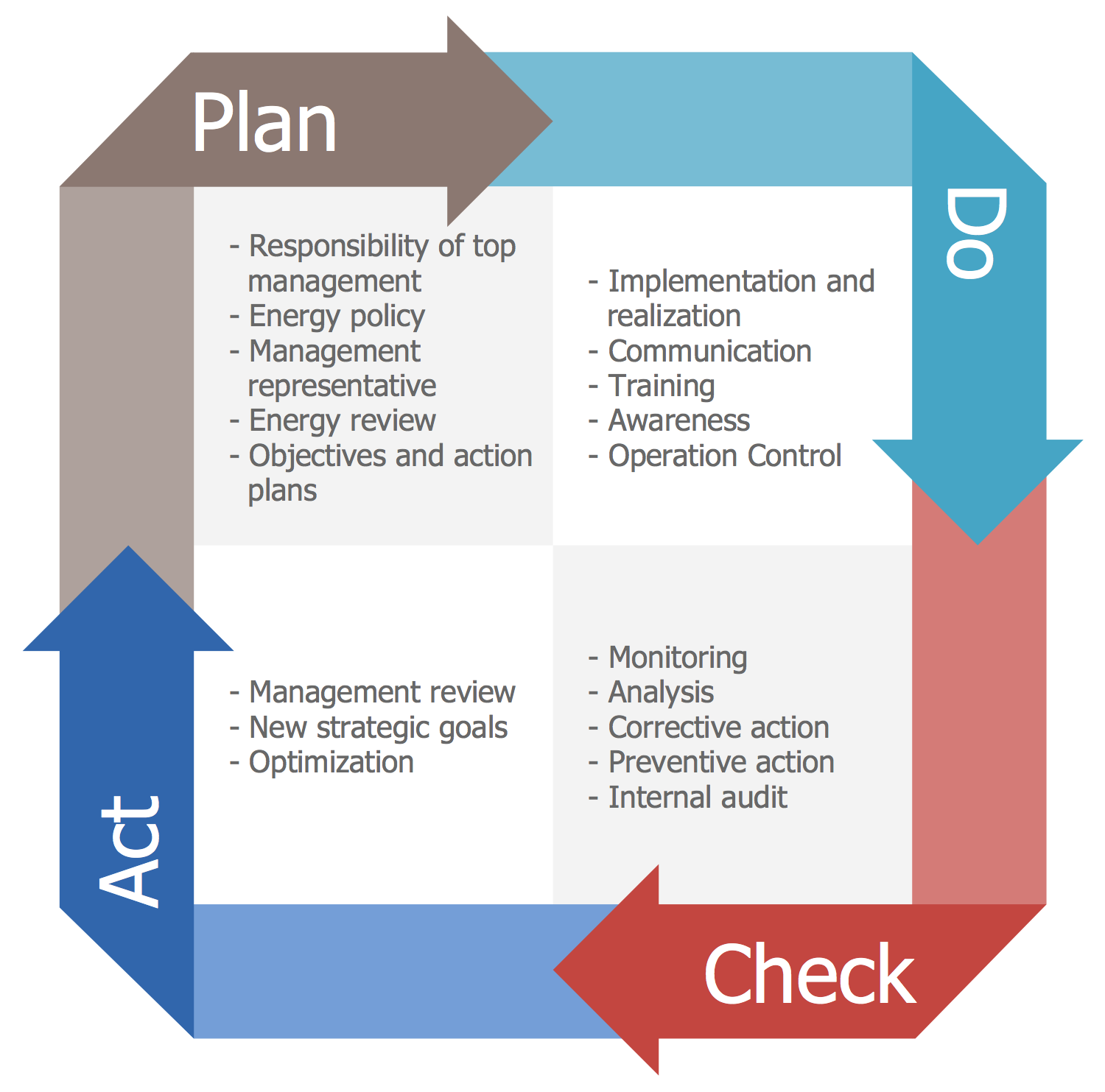

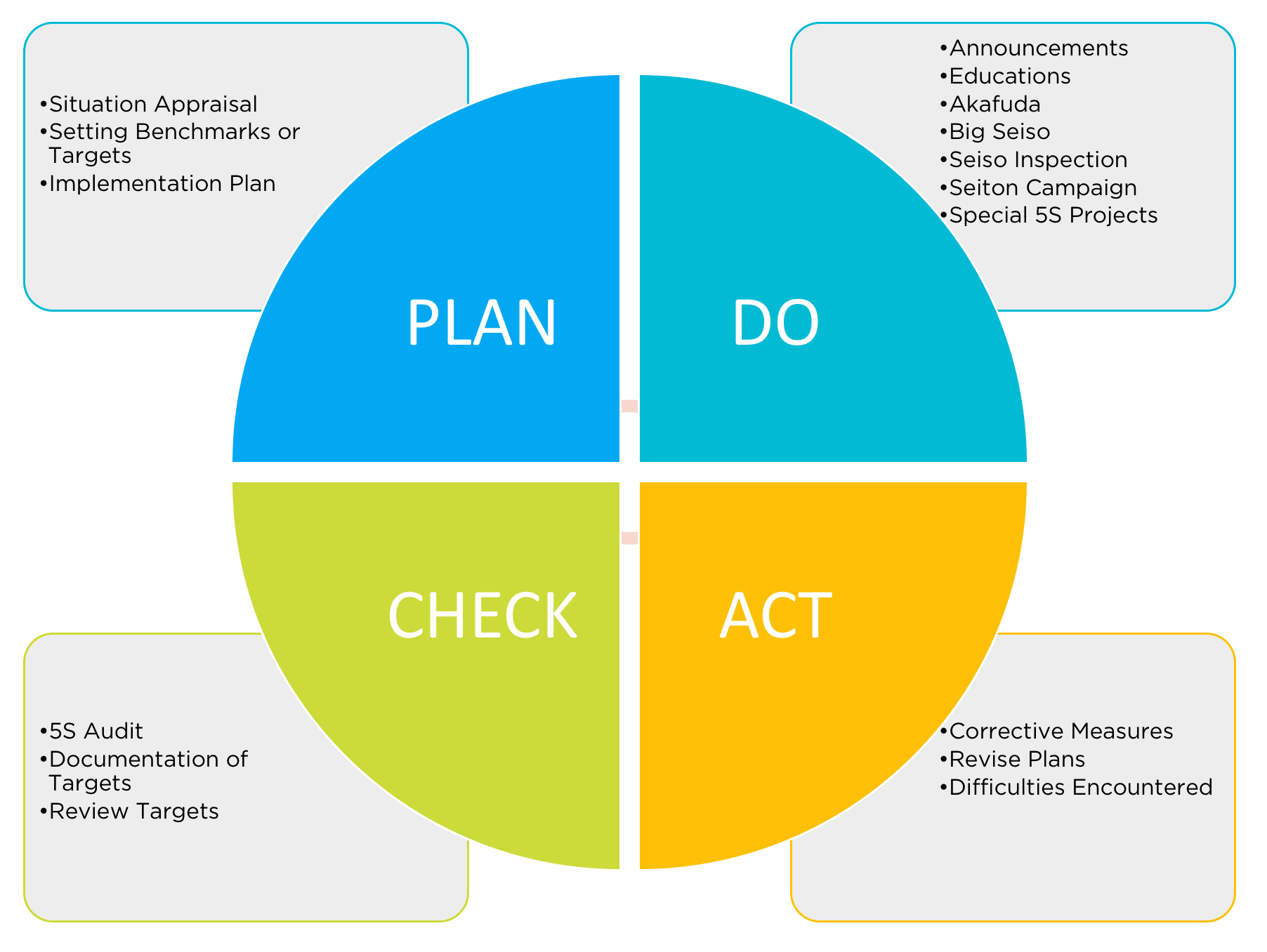

The PDCA cycle has four stages: Plan — determine goals for a process and needed changes to achieve them. Do — implement the changes. Check — evaluate the results in terms of performance. Act — standardize and stabilize the change or begin the cycle again, depending on the results. PDCA is the foundation of continuous improvement or kaizen.

Pdca Cyclus 4 Stappen Plan Do Check Act Voorbeelden Images

PDCA (Plan-Do-Check-Act) is an iterative, four-stage approach for continually improving processes, products or services, and for resolving problems. It involves systematically testing possible solutions, assessing the results, and implementing the ones that have shown to work. It is based on the scientific method of problem-solving and was.

Plan Do Check Act Uitleg Passe IMAGESEE

The Plan-do-check-act Procedure. Plan: Recognize an opportunity and plan a change. Do: Test the change. Carry out a small-scale study. Check: Review the test, analyze the results, and identify what you've learned. Act: Take action based on what you learned in the study step. If the change did not work, go through the cycle again with a.

Plan Do Study Act Template

The plan do check act cycle is not limited to big businesses or specific industries; it can be used by anyone who wants to continuously improve processes. Healthcare. In hospitals, patient care is the most important. By using the PDCA cycle, hospitals can make patient admissions easier, improve treatment plans, and perform better after-care.

How to use a proven method to fix your problems Business West

The PDCA cycle is a process-improving method that involves a continuous loop of planning, doing, checking, and acting. Each stage of the PDCA, meaning the Plan-Do-Check-Act, cycle contributes to the goal of identifying which business processes work and which of them need further improvement. This methodical approach is also utilized to avoid.

.jpg?width=1548&name=PDCA (2).jpg)

PlanDoCheckAct

Plan-do-check-act, or PDCA, is a method organizations use to continually improve their internal processes, increasing the quality of their products and the overall efficiency of their business.

Deming’s PlanDoCheckAct Cycle LaConte Consulting

The Plan-Do-Check-Act model is a particularly useful tool for companies who follow the Kaizen method. Kaizen is an organizational mindset and culture focused on small, frequent changes that lead to significant improvements over time.

PDCA cyclus Plan Do Check Act uitleg 2 Deming cirkels

PDCA Cycle: A four-step problem-solving iterative technique used to improve business processes. The four steps are plan-do-check-act. The PDCA Cycle can be used to effect both major performance.

Plan Do Check Act de PDCAcyclus tilt je bedrijf naar het volgende niveau De Zaak

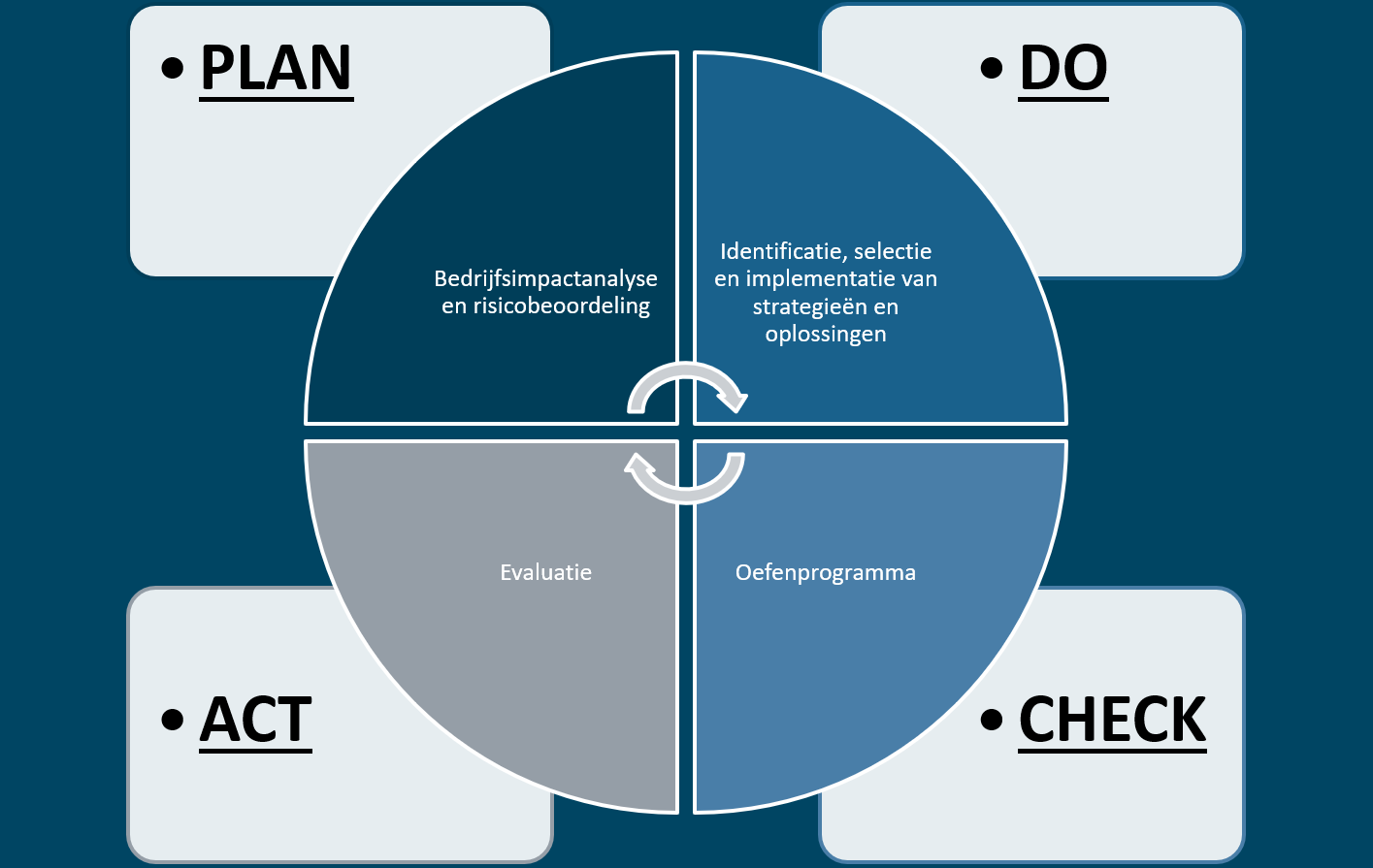

The Plan-Do-Check-Act (PDCA) cycle is a quality management methodology that aims to continuously improve processes.. This continual improvement approach was first developed and used in the 1950s by Dr. William Edwards Deming and since then it gained popularity and is now used by many organizations. Originally, the concept used by Deming was Plan-Do-Study-Act (PDSA), a systematic method used to.

plandocheckactcycle BMC Software Blogs

Act. Plan-Do-Check-Act (PDCA) provides a simple but effective approach to problem solving, managing change, ensuring ideas are appropriately tested before committing to full implementation in the "act" phase. Benefits include: Simple standardized method of improvement. Repeatable and consistent. Serves as an over-arching model for all other.

Plan Do Check Act Model 40 Plan Do Check Act Template in 2020 How to plan / The pdca

The PDCA Cycle is a four-stage iterative framework aimed at continuous improvement. It involves planning (Plan), executing (Do), assessing and analyzing results (Check), and making necessary adjustments and enhancements (Act). This cycle helps organizations improve processes, products, and services over time. Origin.

Plan Do Check Act Template Excel

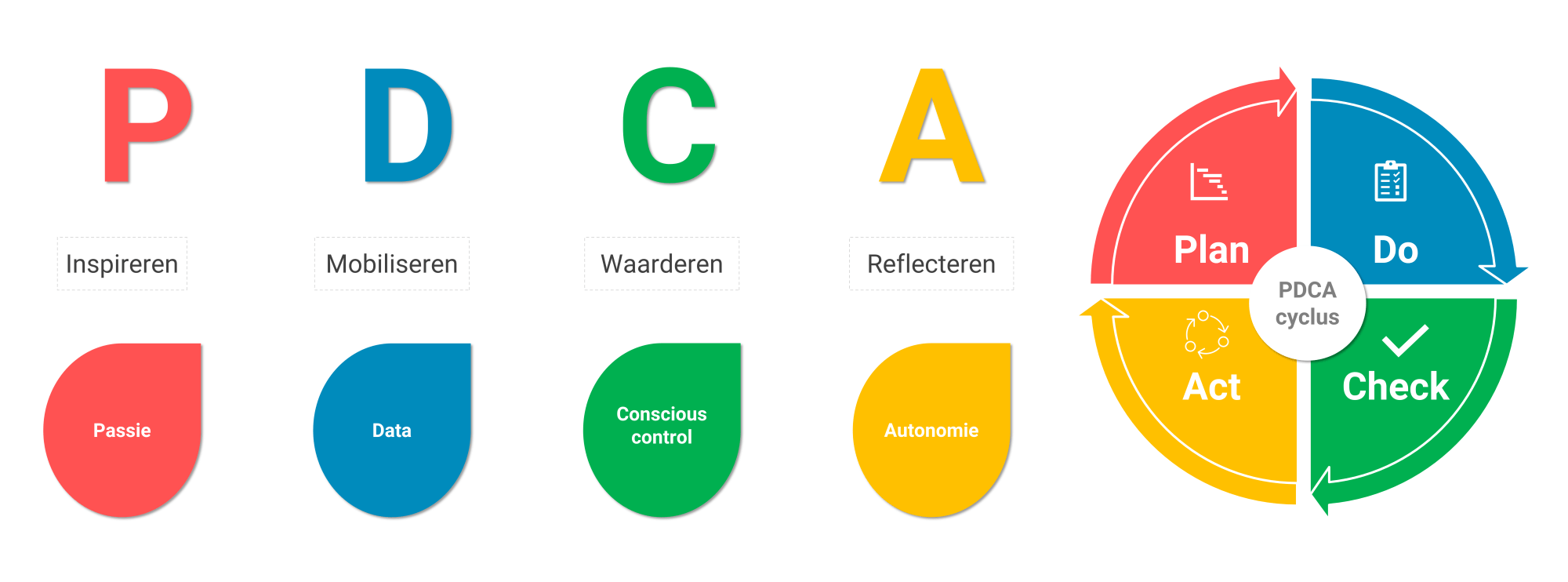

PDCA is een afkorting die staat voor de 4 stappen van de PDCA cyclus Plan Do Check en Act. Je kunt deze stappen als hulpmiddel inzetten om processen te verbeteren en de kwaliteit ervan te verhogen. Met de toevoeging van het woord "cyclus" wordt bedoeld dat het werk nooit af is. Na het doorlopen van de Act fase, maak je nieuwe plannen om het.

PDCA cyclus Plan Do Check Act uitleg 2 Deming cirkels

Plan-Do-Check-Act Cycle (PDCA) is a four-step, iterative by-design method used for control and continual improvement of processes and products. It is also known as the Plan-Do-Study-Act (PDSA) cycle, Deming cycle, Control Circle/Cycle or the Shewhart cycle. The PDCA cycle (Image source: Shutterstock [1]) PDCA is an evidence-based participatory.